my research

Lignin

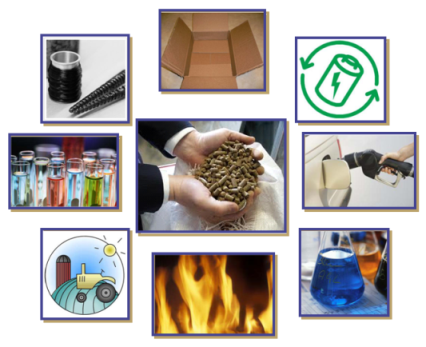

Lignin the second most abundant bio polymer on the planet, with an economical potential that has not yet been fully exploited. Many applications for lignin have been introduced and explored. Replacement of synthetic resins in carbon fiber manufacturing with lignin is one of the great potentials for this renewable bio polymer. However, it is complex to accomplish this on a commercial scale due to lignin’s heterogeneous property, presence of contaminants in commercially available lignin and economical viability. Discovery of a cost effective process which could produce valuable product fractions in the purity required could open the door to future prospects.

Tangential flow filtration

Membrane separation processes have been a topic of extensive research and discussion as of late due to the great interest it garnered as vast arrays of practical application have sprung up in such industries as food, chemical, biological and pharmaceutical. The success of TFF in industry can be attributed to its simplicity. Concentration and purification can be achieved either in small batch to medium scale processes, with the only required necessities being a semi-permeable filter medium and a driving force via hydrostatic pressure. The only main disadvantages associated with TFF being membrane fouling, cleaning cyde and service life span. The degree of the membrane’s effectiveness is dependent on the type of membrane used and cut-off rating. Four process categories can be differentiated: MF (microfiltration), UF (ultrafiltration), NF (nanofiltration) and RO (reverse osmosis). All aforementioned process classifications vary with respect to type of membrane, essential operating conditions and its application field.

|

Lignin seperation with TFF technology

Ultrafiltration is largely accepted as the most practical way of fractionating lignin by molecular weight, confirmed via size exclusion chromatography. The highest fractions present in black liquor are of low molecular weight (LMW) in the range of 5 -15 kDa. Fractions outside of this range are considered more desirable for their added revenue stream potential.

Proposed approach

The main objective for the present work is to fractionate lignin from various pulp and paper mill effluents. One of the key performance parameters for this study is the purity of lignin fractionated. Similar to any process, seeking higher purity of the product could result in sacrificing the productivity and yield. It is therefore key to strive for a balanced approach during process development.

The current approach is designed to evaluate the ultra-filtration effectiveness for isolation of lignin from the Black Liquor (BL) effluent with a high degree of purity. One of the main impurities in commercially available methods to purify lignin is hemicellulose. As mentioned beforehand, the ideal method thus far for separation of lignin and hemicellulose is separation via Ultra-filtration. This study intends to discover a suitable commercially available membrane which will be followed by the optimization of processing parameters to maximize yield. In addition an economical calculation for the scaled up process will be performed to evaluate the commercial viability of the proposed solution.